Positive Displacement Pumps Used in Swimming Pool Care

Positive displacement pumps or positive displacement feeders are used to introduce or add a liquid solution to the water of your swimming pools. Addition of this chemical solution is usually achieved through a connection in your pool circulation system. Your choice of pool chemicals can either be delivered into your pool or spa in either a liquid or dry chemical form.

Dry chemicals that you would add to your water system can be mixed with water.

Once you follow the manufacturer's instructions for mixing your swimming pool chemicals, you can do your mixing right there on site.

When you mix chemicals together, you create a liquid or slurry solution that can be mechanically fed into your swimming pool or spa water.

Whenever you are adding chemicals to adjust the water chemistry of your pools and spas, you should make the addition downstream from your swimming pool filters and pool heater. Unless you are using a venturi injector type system, the pump/s used to deliver the solution must have a high enough effluent pressure.

This requirement will ensure that the liquid solution is properly pumped into your pool circulation line.

The devices that we commonly used for this type of job are usually referred to as positive displacement pumps. Positive displacement feeders are commonly used in the swimming pool industry for injection purposes. Normally they are used for injection of Sodium Hypochlorite and liquid chemicals that are used for pH control.

How To Control pH In Swimming Pools And Spas

This process requires the addition of a pool chemical that is designed just for this task. This is usually accomplished with the addition of Muriatic acid (liquid) or Sodium Bisulfate (dry acid form) or another chemical that can lower your pool pH range.

In some cases, manufacturers will instruct pool operators to dissolve Sodium Bisulfate in an excess of water.

Afterward, they will feed the slurry into the pool by some type of mechanical device. This will cause a reduction in the pH level of the pool. It is extremely important that you read the directions found on the chemical labels.

Types Of Positive Displacement Pumps

All pumps fall into two major groups worldwide. The two categories that the diverse types of pumps fall under are positive displacement and rotodynamic. For now, we are only concerned about the pumps that fall into the positive displacement pumps category.

The reason for this is because these are the type of pumps that are commonly used in the swimming pool and spa industry.

Positive displacement feeders are mechanical feeders that come in two common designs. These designs include:

- The peristaltic pump - This pump uses rollers that squeeze a feed tube. The squeezing process is what forces the liquid through the feeder tube.

- The piston or diaphragm - This pump operates with a check valve.

Installation of your positive displacement pumps is done through a special connection to your pool circulation system. We refer to this special connection as a corporation cock. Using this special connection will allow you to easily remove and clean your connector periodically.

How Do Peristaltic Positive Displacement Pumps Work?

These are positive displacement pumps or feeders that are used for pumping a variety of fluids. The fluids are contained within a flexible tube that are fitted inside a circular pump casing. This design is found on each model of this type of peristaltic pump. A motor-driven rotor with a roller assembly squeezes the flexible tube which forces the fluid into your circulation system.

As the rotor turns, the part of the tube that is under compression, causes a constant volume of fluid to be discharged under pressure. This process occurs every cycle of the rotor assembly. The pressure referred to here is usually about 25 PSI. There are some models that can deliver the fluid at a much higher pressure. Normally about 100 PSI.

Using these types of positive displacement pumps requires you to keep their feed lines clear of any type of sediment clogging. This is true for both the suction and the discharge side (injection point) of your pump. The main source of failure in these types of mechanical pumps is the flexible tube.

It's good practice to always have replacement tubes in your inventory for speedy repairs. This will minimize your downtime considerably if your pump fails.

How To Repair Or Replace A Peristaltic Pump?

Extra precautions should always be taken when you are repairing or replacing peristaltic positive displacement pumps. The manufacturer's guidelines should always be followed. I know many of us may be tempted to take shortcuts when it comes to repairs. However, this is for our own safety and for proper repairs. A little ounce of prevention is always better than a pound of cure.

This extra care is relative to the type of pool chemicals you are pumping into your swimming pools and spas at the time.

Here are a few examples of the type of instructions that you will find in the manufacturer's guidelines:

- Your positive displacement pumps should never be mounted directly above the chemicals that are being pumped. The reason for this is that over time, the fumes from the pool chemicals that are being pumped can damage the peristaltic pump.

- Positive displacement pumps should not be mounted directly over any of your operating equipment. Why? Because, if the flexible tubing of the pump were to fail, the chemicals that are being pumped can be released and cause extensive damage to your equipment which can be very costly.

- You should never mount your peristaltic displacement pump feeder above a different type of chemical other than the one that is being pumped. Again, if the flexible tubing for the pump was to fail, chemicals that are incompatible can accidentally mix...causing an extremely dangerous situation. A mixture of this sort is extremely dangerous because of the toxic gases that are produced and released into the air. This can cause serious injuries or illness or even death to a pool operator.

Regular maintenance on your peristaltic displacement pumps is an absolute must. Why? Because failure to do so will result in clogged lines (flexible tube). This leads to higher-than-normal pressure which causes failure of the flexible tube. The expected life of the flexible tube on these types of mechanical pumps is about four hundred working hours.

Once this time has expired, the flexible tubing should be replaced. Unfortunately, the above working hours of the tubing can be reduced due to extremely poor maintenance and clogged lines.

If you have positive displacement feeders that pump sodium hypochlorite and acid, absolute care must be taken when cleaning the flexible tubing on the unit/s.

You must make sure that they do not encounter each other. If by accident, they do encounter each other, dangerous chlorine gas will be released. Remember safety first!

Positive Displacement Diaphragm Pumps

Positive Displacement Diaphragm PumpsConstruction Of Positive Displacement Diaphragm And Piston Pumps

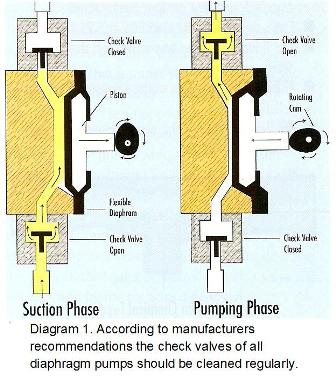

Both positive displacement pumps are similar in that they both use check valves and cams as part of their design.

As for the piston pump, it is activated by its cam head.

The diagram to the right gives us a clear understanding of how these two positive displacement pumps are designed or constructed.

The pump on the right in the diagram is the piston operated one.

How Do Positive Displacement Diaphragm Pumps Work?

Diaphragm pumps are positive displacement mechanical feeders that use a flexible membrane. This membrane is what displaces the fluid in the pump head. Displacement of the fluid is accomplished through a series of in and out movements of the flexible membrane. There are three main types of diaphragm pumps that are commonly used. Examples of these are as follows:

- In the first type, the diaphragm of the pump is sealed. One side is immersed in the fluid to be pumped and the other side is in air or a hydraulic fluid. Operation! The diaphragm is flexed which causes the volume of the pump chamber to increase and decrease. A pair of non-return check valves are used to prevent a reverse in flow of the fluid being pumped.

- In the second type of diaphragm pump, the operation is a little like the first type. This one works with a volumetric positive displacement. However, it differs in that the prime mover of its diaphragm is neither oil nor air. It's electro-mechanical which works through a cranking or geared motor drive. This method causes the diaphragm of the pump to flex through a simple mechanical action. One side of the diaphragm is open to the air.

- The last of the three types of diaphragm pumps has one or more unsealed diaphragms. The fluid that is to be pumped using this type, is on both sides of the diaphragm. Again, the actions of the diaphragm/s cause the volume of the pump to change.

Installation Of Positive Displacement Diaphragm Feeders

When using positive displacement pumps, the feed rate of your pool chemical is determined by the cycle rate of the cam or solenoid. The check valves in a diaphragm pump are spring loaded. Installation of these types of mechanical feeders requires the use of four check valves for every pump installed.

The check valves are installed as follows:

- One at the strainer end of the suction line. This is in your chemical vat or mixing drum.

- One at the entrance side of the feeder pump (just before the fluid enters the pump head).

- One on the exit side of the pump head (discharge side of the feed pump).

- One at the point of injection of the chemical fluid.

Anytime you have a failure with any of these check valves, your disinfection system is in trouble. This means that you are not maintaining a proper level pool water chemistry. Sanitation of your swimming pool and spas would be ineffective.

To help avoid any type of failure to these check valves, it is recommended that we flush our positive diaphragm pumps regularly.

This should be at least once a week.

How a Piston Operated Positive Displacement Pump Work?

The function of piston operated positive displacement pumps, are like that of the diaphragm pumps.

However, there is one exception. The out port or discharge pressure of the pump is created by the movement of pistons. The same care and recommendations for cleaning or flushing the feed lines still apply.

Maintaining the water chemistry for your swimming pool or spa is a daily task 24/7. Unfortunately, we cannot be policing our water facilities 24 hours a day, or can we? Using the right automatic electronic controllers and mechanical feeders and pumps, we can accomplish this task effectively. Again...examples of some of the mechanical feeders are positive displacement pumps.

Positive displacement pumps are a big part of your chemical feed system!

New! Comments

Have your say about what you just read! Leave me a comment in the box below.